Minimizing Finished Product Loss with VXP

Focus on the Cost of Finished Product Loss

Every beer distributor faces a common challenge: Finished Product Loss (FPL). Whether it’s out-of-code beer, close-to-code inventory, breakage, or returned products that can’t be resold, FPL represents a significant drain on profitability. While it’s often treated as a cost of doing business, failing to track and manage it effectively can lead to hundreds of thousands of dollars in avoidable losses each year.

Traditional inventory management practices often focus on pushing volume, but if that volume isn’t moving efficiently, distributors end up absorbing unnecessary costs. VXP gives your team the tools to track, analyze, and ultimately reduce FPL—turning what was once a silent margin killer into a managed expense.

Understanding the Sources of Finished Product Loss

Distributors that don’t actively monitor and manage FPL typically experience loss in three major areas:

Out-of-code product

Beer that wasn’t sold before its expiration date, often due to overordering, poor inventory rotation, or mismatched product placement.

Close-to-code Product

Product that isn’t expired yet but is at risk of not selling before it goes out of code, requiring reverse logistics to redistribute it.

breakage & Returns

Damaged or broken product, as well as returned cases that can’t be resold due to packaging integrity, improper handling, or supplier policy.

These losses don’t just hurt gross profit—they create operational inefficiencies, add extra work for warehouse and delivery teams, and tie up resources that could be used elsewhere.

“If we don’t track FPL, we have no idea where the problem is or how deep it goes”

Mikey Hall

Former Operations Manager

The VXP Approach:

From Tracking to Action

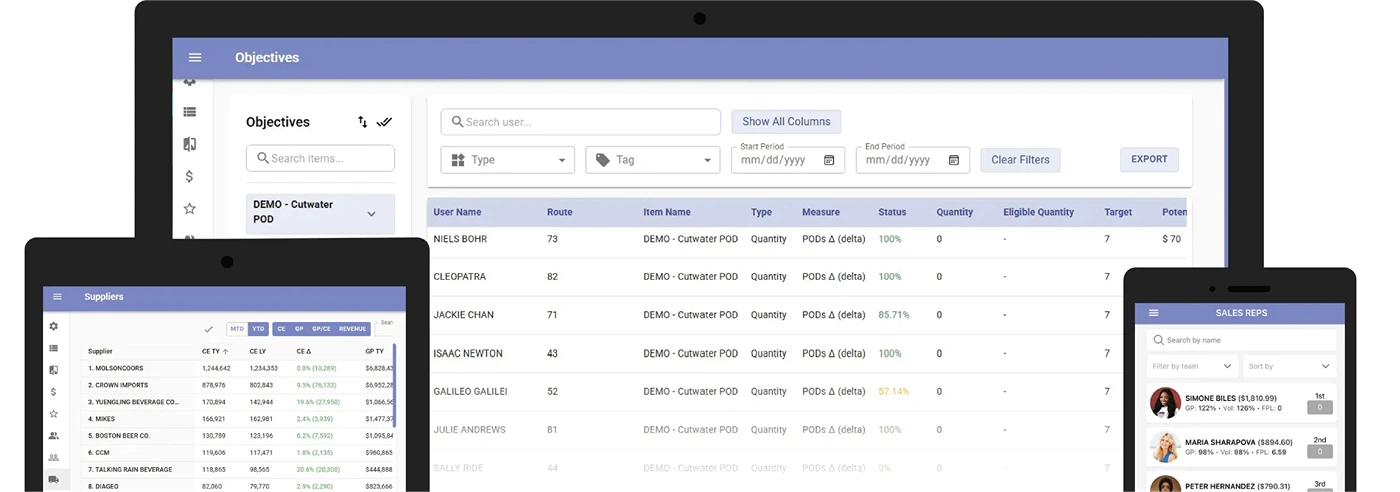

Many distributors track FPL passively, looking at a lump sum loss on their P&L at the end of the year. But that doesn’t drive accountability or provide insights on where losses are happening. VXP changes that by giving you the ability to track FPL at the route, rep, and brand level—every day.

How VXP Helps You Reduce Finished Product Loss

- Tracking in Real-Time: VXP integrates with your route accounting system (VIP, Encompass, etc.) to track FPL by reason code—out-of-code, close-to-code, breakage, returns—at the invoice level.

- Accountability at Every Level: Instead of treating FPL as a sunk cost, VXP incentivizes sales reps to minimize losses, turning finished product loss into an actionable metric.

- Insights to Drive Change: Sales teams see the financial impact of their decisions, helping them identify problem areas like overordering, poor execution on displays, or slow-moving SKUs.

- Balancing Volume with Profitability: VXP ensures that growth strategies include sell-through velocity and profitability metrics, so you’re not just placing cases—you’re placing the right cases in the right accounts.

Building a Smarter

Compensation Strategy

Distributors that want to truly control Finished Product Loss need to align their incentive structures to reward smart inventory management. VXP enables:

- Tiered Bonus Structures – Reps who keep their FPL below a set threshold receive a higher payout on their variable compensation.

- Cents Per Case Tracking – If a rep’s FPL goes above a certain cost per case, their bonus is reduced proportionally—creating a direct incentive to keep product moving efficiently.

- Team-Based Peer Accountability – In many VXP-powered wholesalers, FPL is tracked as a team metric, creating peer-driven pressure to avoid unnecessary losses.

“There’s no pressure like peer pressure. When a rep is dragging the team down, everyone steps in to help move slow-moving inventory before it becomes a loss.“

Mikey Hall

Former Operations Manager

Reducing Warehouse-Generated FPL

While much of FPL occurs in the trade, warehouses also contribute to finished product loss. Over-ordering, incorrect forecasting, and improper storage practices can lead to expired product sitting in the warehouse before it even reaches a retail account. VXP helps you:

- Tighten Supplier Ordering: Use historical FPL data to push back on supplier-recommended orders that don’t align with your territory’s sell-through trends.

- Monitor Seasonal Trends: Avoid ordering too much holiday-themed or seasonal product that will be unsellable after the season ends.

- Hold Brand Managers Accountable: Ensure that those overseeing supplier relationships aren’t overcommitting to products that won’t move in your market.

Why Now?

Traditional approaches to FPL aren’t cutting it. If your losses are continuing to mount, it’s time to implement a system that actively reduces finished product loss instead of just reporting on it.

New VXP Distributors typically see their FPL decrease by 50% within 12 months, thanks to a combination of visibility, accountability, and behavioral incentives.

Are you ready to stop throwing money away and start taking control of your Finished Product Loss?

Ready to transform your sales

process with cutting-edge analytics?

Contact us today to see how VXP can help you build a more profitable, waste-free distribution model.